Installing stormwater management systems

It seems to have become the norm for many contractors to want to place orders for stormwater attenuation tanks on a supply and install basis. You can see why when you fully understand what is involved with the installation of crates. No, it’s not the stacking of the blocs or the clipping them together, of course really anyone can do that bit. It’s the welding of the geomembrane. The most important part of the whole tank when you think about it.

All the crates are doing is creating a large void underground. It’s the fact that they’re wrapped and sealed in a completely watertight liner that they actually perform a job. Of course, they have to be structurally sound and capable of withstanding whatever loading may be placed above them on the finished surface level, but the truth is that the crates are just a means to an end. The truth is that without being used in combination with the 1mm thick LLDPE geomembrane liner, they’re no use to anyone! (unless you’re creating a soakaway/infiltration tank that is) It’s the water-tightness of the membrane, especially the welded seams of the membrane, that are crucial to the actual performance of the tank. That’s why orders get placed on a supply and install basis.

The added benefit when you place orders with a specialist on a supply & fit basis, is that you know it will be done in the quickest and most effective way possible, with a guarantee that the sealed membrane is watertight.

Step by step guide to installing a stormwater attenuation tank

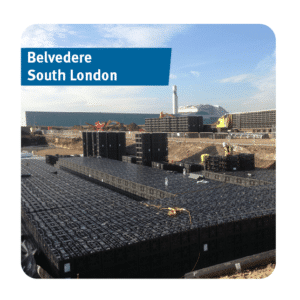

8x images & text from inside cover of SWM display box